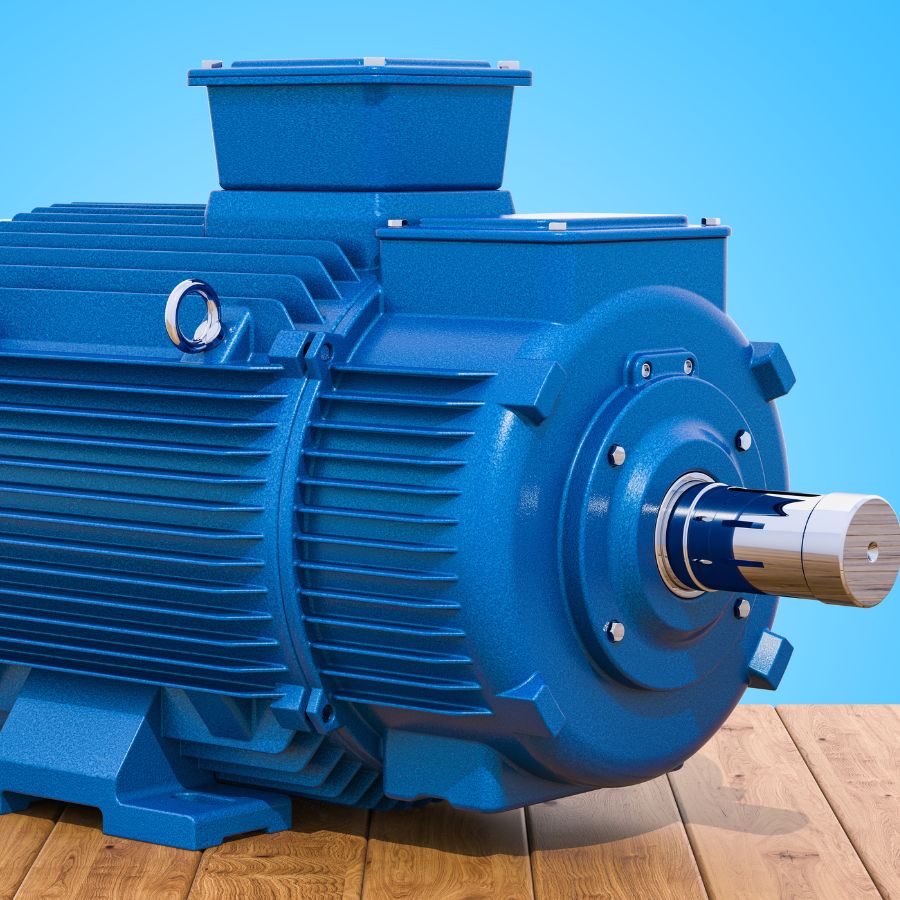

In an industrial environment with machinery and automated systems, electric motors pump life into numerous devices, operations, and appliances. From powering industrial machinery to driving household appliances, these motors form the backbone of modern civilization.

Like any mechanical device, their performance can decrease over time due to many factors. By understanding the reasons for electric motor failure, you can optimize your decision-making, enhance operational efficiency, and secure long-term cost-effectiveness.

The bearings in an electric motor allow the rotor to turn smoothly and deliver consistent results. If these bearings fail, it can cause the motor to run erratically, reducing its power and efficiency. Maintenance and lubrication can help you avoid bearing failures and maintain the motor’s power output.

Faulty or damaged windings can also lead to a decrease in power output. Windings are wires wound around the motor’s rotor, and if they suffer damage, they can limit the electric current flow, leading to reduced power. Rewinding the motor can often solve this problem, although a replacement may be necessary in severe cases.

General wear and tear can lead to a loss of power in electric motors. As motors age, their parts can wear out. Repairing vs. replacing your electric motor depends on the deterioration stage of all the components. Regular maintenance can help you identify any problems to maintain the motor’s power output and not require a total replacement.

One of the common causes of power loss in electric motors is overheating. Overheating can happen from extended periods of operation, a lack of cooling, or operating in an environment with high ambient temperatures. When a motor overheats, its windings may suffer some damage, leading to decreased power output. Regular inspections and proper cooling can prevent this issue.

Electric motors require a steady voltage supply to operate effectively. You must ensure you have this connection before getting this type of motor. Voltage fluctuations or drops can cause the motor to lose power and sometimes suffer damage, so ensure that the power source supplying the motor is reliable.

Understanding the issues that can lead to power loss in your electric motor can help you make informed decisions about maintenance and when it’s more cost-effective to replace the motor. Regular inspections, maintenance, and dealing with issues promptly can prolong your motor’s life and ensure it continues to deliver the power you need.

24World Media does not take any responsibility of the information you see on this page. The content this page contains is from independent third-party content provider. If you have any concerns regarding the content, please free to write us here: contact@24worldmedia.com

Common Mistakes When Using Athletic Field Tarps

High-Performance Diesel Truck Upgrades You Should Consider

Warehouse Optimization Tips To Improve Performance

Fire Hazards in Daily Life: The Most Common Ignition Sources

Yellowstone’s Wolves: A Debate Over Their Role in the Park’s Ecosystem

Earth Day 2024: A Look at 3 Places Adapting Quickly to Fight Climate Change

Millions of Girls in Africa Will Miss HPV Shots After Merck Production Problem

This Lava Tube in Saudi Arabia Has Been a Human Refuge for 7,000 Years

Four Wild Ways to Save the Koala (That Just Might Work)

National Academy Asks Court to Strip Sackler Name From Endowment

Ways Industrial Copper Helps Energy Production

The Ins and Out of Industrial Conveyor Belts